HONDA VALVE TECHNOLOGY

1. Introduction

VTEC (Variable Valve Timing and Lift Electronic Valve) is a valve

train system developed by Honda to improve the volumetric efficiency of a four

stroke internal combustion engine. The VTEC system uses two camshaft profiles

and hydraulically selects between profiles. It was invented by Honda engineer

Ikuo Kajitani, and was the first system of its kind. VTEC was initially

designed to increase the power output of an engine to 100 HP/liter or more

while maintaining practicality for use in mass production vehicles. Some later

variations of the system were designed solely to provide improvements in fuel

efficiency. Japan levies a tax based on engine displacement, and Japanese auto

manufacturers have correspondingly focused their research and development

efforts toward improving the performance of smaller engine designs through

means other than displacement increases. One method for increasing performance

into a static displacement includes forced induction, as with models such as

the Toyota Supra and Nissan 300ZX which used turbocharger applications and the

Toyota MR2 which used a supercharger for some model years. Another approach is

the rotary engine used in the Mazda RX-7 and RX-8. A third option is to change

the cam timing profile, of which Honda VTEC was the first successful commercial

design for altering the profile in real time. The VTEC system provides the

engine with multiple camshaft profiles optimized for both low and high RPM

operations. In basic form, the single cam profile of a conventional engine is replaced

with two profiles: one optimized for low RPM stability and fuel efficiency, and

the other designed to maximize high-RPM power output. The switching operation

between the two cam lobes is controlled by the ECU which takes account of

engine oil pressure, engine temperature, vehicle speed, engine speed and

throttle position. Using these inputs, the ECU is programmed to switch from the

low lift to the high lift cam lobes when the conditions mean that engine output

will be improved. At the switch point a solenoid is actuated which allows oil

pressure from a spool valve to operate a locking pin which binds the high RPM

cam follower to the low RPM ones. From this point on, the valves open and close

according to the high lift profile, which opens the valve further and for a

longer time. The switch over point is variable, between a minimum and maximum

point, and is determined by engine load. The switch down back from high to low

RPM cams is set to occur at a lower engine speed than the switch up

(representing a hysteresis cycle) to avoid a situation in which the engine is

asked to operate continuously at or around the switch over point. The older

approach to timing adjustments is to produce a camshaft with a valve timing

profile that is better suited to high RPM operation. The improvements in high

RPM performance occur in trade for a power and efficiency loss at lower RPM

ranges, which is where most street-driven automobiles operate a majority of the

time. Correspondingly, VTEC attempts to combine high-RPM performance with low

RPM stability.

2. History

As known, Honda is the master of valve technology. Honda valve system is

invented by Honda engineer Ikuo Kajitani, and was the

first system of its kind.

During the early 1980s, in

fact-and none of it had anything to do with automobile engines. The technology

behind VTEC originated from Honda's motorcycle side. Honda's engineers knew

that four-valve engines made great top-end power, but that two-valve ones were

competent down low and even idled nice. The quest soon became one in which a

500cc engine would spin to 11,000 rpm yet idle patiently at a mere 1,000 rpm.

The result was what Honda internally labeled as its "REV" mechanism,

or "HYPER VTEC" to the rest of us. The technology allowed for only

one intake and one exhaust valve per cylinder to operate below certain engine

speeds but for two intake and two exhaust valves per cylinder to function above

that threshold. It allowed for the best of both worlds.

Honda launched the NCE (New

Concept Engine) project in 1984, which aimed to push the limits of top-end

torque production without sacrificing low-end performance. Japanese-market '85

Civic and Integra engines were the result of this project. More importantly

though, it convinced engineers that a dual-camshaft profile-or a mechanism that

could dynamically alter camshaft timing-must be a part of the company's

next-generation engine. Engineer Ikuo Kajitani, who was a part of the NCE team,

was particularly enthusiastic about making this happen. The ideal engine would

have better fuel economy and a higher output across the entire powerband,

specifically, about 90 hp per liter. But 90 hp soon began to seem too low; it

was, after all, only 10 more than the engine they'd just produced. Based on the

suggestion of then Honda R&D president Nobuhiko Kawamoto, a new goal of 100

hp per liter was set.

"It felt like a

dream," Kajitani recalled. "Conventional engines in those days could

only produce 70 or 80 hp per liter. But here we were, being asked to increase

it all the way to 100 horses. It wasn't going to be easy. An engine becomes

subject to a higher load as you increase its rpm," Kajitani said.

"So, we had to keep in mind the quality-assurance target of 15 years, or

250,000 km, for a mass-production engine. We all wondered how on earth we were

going to reach that number while ensuring the required quality of mass

production." After all was said and done, Kajitani officially set the goal

for the new VTEC Integra engine: 160 hp and an 8,000rpm redline. A goal is one

thing, but the technology had yet to be created. All of this led to daily

arguments as to whether or not such an engine was even possible. After three

months, Kajitani put it all on the line, ordering his team to move forward. A

technology proposal would soon be chosen and developed.

(The "Type R"

moniker is likely responsible for cementing VTEC's power status into enthusia)

Of course, we know the

results, but the time spent developing VTEC proved to be as fascinating as the

final product. Take the camshaft gears for example, engineers elected to build

these out of a new high-strength sintered alloy for a thinner profile and a

10-percent lower moment of inertia. The intake valves were increased to 33mm, a

then unheard of size for such a small engine. The VTEC valve timing and lift

specs were similar to race-only engines of that period. To prevent breakage,

VTEC camshafts were made from a completely new high-carbon, high-chrome cast

steel alloy, which was given a combination of heat and surface treatments. Even

the exhaust valves were made of nickel-based, heat-resistant steel combined

with molybdenum, titanium, and tungsten-not your average mid-'80s, economy car

technology. And all of this had to be durable. This is perhaps where Kajitani's

team did its greatest work. Gearboxes, crankshafts, and many other Honda

components have become legendary for the abuse they can handle. "That's

why we so thoroughly carried out our malicious tests," Kajitani said.

"We were very near the point of overdoing it." Building a VTEC pin-engagement

system that could endure 400,000 cycles is arguably a masochistic endeavor. No

one knew the impact that VTEC would have. It's likely that, in Japan, there

were smiles, but the reality was that Honda was a much smaller player in its

homeland, so even there such an event fell short in terms of hype and would

have been paled by things like the introduction of the new GT-R. Today is

different; you're reading a magazine devoted entirely to the brand. The rest,

as they say, is history.

(The H22A had long been

considered the big-block among the four-cylinder Honda world.)

America's first exposure to

VTEC came in the form of the '91 NSX. However, because of the NSX's supercar

personality-in terms of price and availability-the '92 Integra GS-R is often

credited as being the U.S.'s first real taste of VTEC. Yes, the D16Z6 was

released around the same time, but SOHC VTEC powerplants simply didn't excite

anyone back then. By 1994, Honda had its pieces in place and was poised to put

its competition in checkmate. The company released three powerhouses

practically at once: the redesigned Integra GS-R's B18C, the Prelude Si VTEC's

H22A, and the Del Sol Si's B16A. Combine that with the attention that the

second-generation CRX and '88-current Civics had garnered for themselves and

the company soon had the makings for a new super drug. The sport compact

juggernaut as we know it was just getting started, and Honda's timing couldn't

have been better. It's possible that VTEC even turned the sport compact

molehill into the mountain that it is now; today, there are companies that

exist because of it. Sure, many would modify Hondas were VTEC to never exist,

but it'd be like swimming in the kiddy pool.

Hasport is one such business.

Everyone knows that the GS-R's B18C is cool, but it's even cooler when swapped

into a lighter, smaller '92 Civic hatchback. To be fair, the business of engine

swapping is an industry of its own. Just think: if it weren't for engine swaps,

the GS-R wouldn't top the country's most-stolen-cars list year after year. When

asked where he thought he might be had VTEC never been invented, Brian

Gillespie, Hasport's front man simply said, "I'd be a tennis pro! I'd

recently started working for my brother at his Honda-only junkyard with the

promise of my own racecar. I'd grown up racing motocross, and my brother's '90

CRX was really fast. But honestly, if I hadn't taken the bait, I'd still be

teaching tennis and driving my Volkswagen GTI. That was the only real alternative

to Honda and that is what I would be driving and modifying if it weren't for

VTEC."

(Looking at these power

curves is the easiest way to see just how effective VTEC is.)

ECU tuning company Hondata

owes homage to VTEC arguably as much as companies like Hasport. The company was

started by a couple of Kiwis who had a passion for racing and continue to

today. Co-owner Doug MacMillan says, "We built our business around what

the aftermarket tuning community was doing with Honda engines, especially

forced induction. It's fairly safe to say that modifying Honda engines has been

central to the sport compact car scene and the VTEC system has allowed Honda to

stand head and shoulders above the crowd. Had Honda not created VTEC, Honda

would have been more like one of the crowd with fewer people selecting their

cars and engines for modification. We would still be doing what we are now,

which is building great programmable engine management systems for Hondas and

Acuras, but we would be doing fewer of them."

But what about racing?

Although the need to implement VTEC into Honda's championship Formula 1 engines

wasn't there, the technology played a major role in early import drag racing.

When asked how VTEC helped shape sport compact drag racing, long-time drag

racer Stephen Papadakis says, "The VTEC cars weren't as fast as the

non-VTEC ones until 1997 or so. The scene was well on the way at that

time." This is likely true; Mitsubishi's DSMs had been out for some time

and tuners were getting decent numbers from non-VTEC Honda engines. "When

the '94 Integra GS-R came out, that was when Japan finally gave the U.S. market

a good engine. That car was fast! That was when VTEC changed from trendy to

fast, in my experience," Papadakis says.

The late '90s was an

explosive time for Honda enthusiasts. The GS-R was selling in large numbers and

Honda finally got wise and released the B16A-equipped Civic Si. The VTEC

experience was so strong for one old-school gearhead that he went so far as to

purchase a brand new Si just for development purposes. Up until the release of

the '99 Si, John Grudynski, owner of HyTech Exhaust, had only manufactured his

custom-made headers for race cars, Formula Fords, Indy cars, and other spec

classes. He was soon hooked on VTEC though. "It was 1998 and Dan Paramore

took me for a ride in an ITR and I was blown away with the performance of it. I

didn't even know what VTEC was or how it worked then, but it sure peaked my interest

for sure. The rest is history," John says. Today, HyTech's Honda-specific

headers work so well that they've been copied time and again, despite the

company's best efforts to keep its designs exclusive. While many recognize the

value of a HyTech-style header, only a select few pay for the real thing.

Despite the piracy, John says that without VTEC and Honda's popularity, he'd be

homeless. "About one-third of my business is from [Hondas], the rest is

the Formula car stuff and miscellaneous junk," he says.

(Later VTEC systems switched

to a roller rocker configuration to reduce friction.)

It's difficult to quantify

the impact that VTEC's had on the average enthusiast, but I can do so for

myself-it had to do with a brand-new '94 Integra GS-R, one in which I paid the

full sticker-price for. It may sound strange today, but the purchase was a tossup

between the GS-R and a Ford Probe GT. As odd as it may sound, the Probe was a

serious sport compact contender in 1993. It wasn't bad looking and its V-6 made

nearly as much power as the 170hp Integra. Today, there's little I remember

about test-driving the Probe. The GS-R is a different story. It was visceral,

so much so that I remember details about that day that I shouldn't, like the

shirt I was wearing. It's like mental playback in IMAX. I wasn't going all that

fast and I found myself in Third, so I floored it. Not too impressed initially

but then came the "boom," and the engine's tone changed completely.

As I let off the gas and my sphincter unloaded a brick I contemplated just how

much this blown-up VTEC engine was going to cost me. As I coasted down I

realized that the engine was still running, that and the fact that the tie-guy

sitting next to me was laughing at me. "That's the VTEC," he says.

"Come on, go again, but don't lift off, it's supposed to do that."

There was no use hiding the embarrassment; I just obeyed, this time using

Second gear since we'd slowed so much. Bam! It came again and then, seemingly,

a mere half-second later, once again. I almost lifted, but I kept getting the

"go-go" hand signal from the passenger seat. Up through Third and far

beyond the speed limit, there was just no way I was going to buy anything else.

Twice on the way back, I deliberately slowed down just to hear it kick in

again...the sound, the pull, the way it would go to 8,000 rpm so easily.

Despite the years of screwing around with cars, up until this moment, there had

been nothing like it. Later on at the dealership as I'm looking under the hood

drooling at the site of the engine, I notice that the air filter was exposed. I

asked the salesman if it was supposed to be like that and he says, "No, we

take the lid off so it makes more noise when VTEC turns on." My head

clocks from the filter back to him, and there's his wide smile. No wonder they

were getting full sticker price for these cars and I was stuck waiting for the

next shipment.

Others have had similar

experiences. Larry Widmer, owner of Endyn, says, "In 1992 I was driving my

Civic Si and a kid in a '92 GS-R decided to test me. I won the impromptu street

race...barely. The kid followed me to a nearby parking lot and we looked over

each other's equipment. From the sound change his car made, I figured he had

nitrous, but it turned out to be the VTEC event. He took me for a ride and I

was amazed at how hard the relatively stock car pulled. I remember thinking, 'what

a great thing Honda's come up with.'"

When it comes to competing

technologies, they're out there, but nothing seems to touch VTEC. Today, nearly

all automakers offer variable valve timing, or VTC as Honda now refers to it

for its K-series engines. It wasn't until recently that other automakers

implemented a true variable-lift system in its engines though. Now the new

370Z, the Porsche 911, and BMW engines all have it. And there are others.

Interestingly enough, those that have the VTEC-style moniker on them don't even

have variable lift. The Evo's MIVEC engine only has variable camshaft

timing-not lift-even though the original MIVEC iteration featured both, just

like today's i-VTEC.

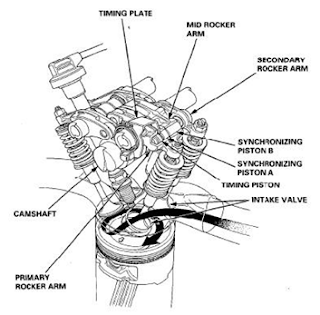

(Notice the mini rocker arm

in the exploded view that's responsible for the variable lift.)

Honda's since aimed to take

its technology one step further with continuously variable valve lift, the

so-called holy grail of the combustion process. An electronic or pneumatic

valvetrain could accomplish this. The premise is that the valve would open any

amount, at any time. Patents have been filed and it even has a name:

A-VTEC-another clever acronym that, this time, stands for Advanced VTEC.

Unfortunately, budgets and a slowing demand have put A-VTEC in the tech freezer

for the time being. BMW's similar Valvetronic system has gone into production,

however, so maybe there is a future for A-VTEC.

It's somewhat amazing, 20

years later, to reminisce at what exactly VTEC's done for Honda enthusiasts.

Love it or hate it (you only hate it when a VTEC engine beats your non-VTEC

engine), this is the stuff that will go into the engine halls of fame. Mad Max

was released in 1979. Instead of the Fast and Furious 4, Hollywood should do a

Mad Max remake, one that depicts the realities of a huge fuel crisis where

turbo Civics and Integras kick everyone else's asses. Or, as Papadakis puts it,

"We raced with a 650-800hp H22A VTEC engine for years with no porting and

stock cams. That just shows the potential of what Honda developed and sold to

the general public."

THE REVOLUTION OF HONDA

VTEC ENGINE

VTEC system has been develop more advance and more efficiently years by years. Here are the revolution Honda’s Valve technology.

VTEC system has been develop more advance and more efficiently years by years. Here are the revolution Honda’s Valve technology.

Introduced as a DOHC system in Japan

in the 1989 Honda Integra X Si which used the 160 bhp (120 kW) B16A

engine. The same year, Europe saw the arrival of VTEC in the Honda CRX 1.6i-VT,

using a 150 bhp variant (B16A1). The United States market saw the first

VTEC system with the introduction of the 1991 Honda NSX,

which used a 3-litre DOHC VTEC V6 with 270 bhp (200 kW). DOHC VTEC

engines soon appeared in other vehicles, such as the 1992 Acura Integra GS-R (B17A1 1.7-litre

engine), and later in the 1993 Honda Prelude VTEC

(H22A 2.2-litre engine with 195 hp) and Honda Del Sol VTEC

(B16A3 1.6-litre engine). The Integra Type R (1995–2000)

available in the Japanese market produces 197 bhp (147 kW;

200 PS) using a B18C5 1.8-litre engine. Honda has also continued to

develop other varieties and today offers several varieties of VTEC, such as

i-VTEC and i-VTEC Hybrid. http://www.youtube.com/watch?v=UEtm2y1yXnI

As popularity and marketing

value of the VTEC system grew, Honda applied the system to SOHC (Single Over Head Cam) engines, which

share a common camshaft for both intake and exhaust valves. The trade-off was

that Honda's SOHC engines benefitted from the VTEC mechanism only on the intake

valves. This is because VTEC requires a third center rocker arm and cam lobe (for

each intake and exhaust side), and, in the SOHC engine, the spark plugs are

situated between the two exhaust rocker arms, leaving no room for the VTEC

rocker arm. Additionally, the center lobe on the camshaft cannot be utilized by

both the intake and the exhaust, limiting the VTEC feature to one side.

However, beginning with the

J37A4 3.7L SOHC V6 engine introduced on all 2009 Acura TL SH-AWD models, SOHC

VTEC was incorporated for use with intake and exhaust valves. The intake and

exhaust rocker shafts contain primary and secondary intake and exhaust rocker

arms, respectively. The primary rocker arm contains the VTEC switching piston,

while the secondary rocker arm contains the return spring. The term

"primary" does not refer to which rocker arm forces the valve down

during low-RPM engine operation. Rather, it refers to the rocker arm which

contains the VTEC switching piston and receives oil from the rocker shaft.

The primary exhaust rocker

arm contacts a low-profile camshaft lobe during low-RPM engine operation. Once

VTEC engagement occurs, the oil pressure flowing from the exhaust rocker shaft

into the primary exhaust rocker arm forces the VTEC switching piston into the

secondary exhaust rocker arm, thereby locking both exhaust rocker arms

together. The high-profile camshaft lobe which normally contacts the secondary

exhaust rocker arm alone during low-RPM engine operation is able to move both

exhaust rocker arms together which are locked as a unit. The same occurs for

the intake rocker shaft, except that the high-profile camshaft lobe operates

the primary rocker arm.

The difficulty of

incorporating VTEC for both the intake and exhaust valves in a SOHC engine has

been removed on the J37A4 by a novel design of the intake rocker arm. Each

exhaust valve on the J37A4 corresponds to one primary and one secondary exhaust

rocker arm. Therefore, there are a total of twelve primary exhaust rocker arms

and twelve secondary exhaust rocker arms. However, each secondary intake rocker

arm is shaped similar to a "Y" which allows it to contact two intake

valves at once. One primary intake rocker arm corresponds to each secondary

intake rocker arm. As a result of this design, there are only six primary

intake rocker arms and six secondary intake rocker arms.

The earliest VTEC-E

implementation is a variation of SOHC VTEC which is used to increase combustion

efficiency at low RPM while maintaining the mid range performance of non-vtec

engines. VTEC-E is the first version of VTEC to employ the use of roller rocker

arms and because of that, it forgoes the need for having 3 intake lobes for

actuating the two valves - two identical lobes for non-VTEC operation and one

lobe for VTEC operation. Instead, there are two different intake cam profiles

per cylinder - a very mild cam lobe with little lift and a normal cam lobe with

moderate lift. Because of this, at low RPM, when VTEC is not engaged, one of

the two intake valves is allowed to open only a very small amount due to the

mild cam lobe, forcing most of the intake charge through the other open intake

valve with the normal cam lobe. This induces swirl of the intake charge which

improves air / fuel atomization in the cylinder and allows for a leaner fuel

mixture to be used. As the engine's speed and load increase, both valves are

needed to supply a sufficient mixture. When engaging VTEC mode, a pre-defined

threshold for MPH (must be moving), RPM and load must be met before the

computer actuates a solenoid which directs pressurized oil into a sliding pin,

just like with the original VTEC. This sliding pin connects the intake rocker

arm followers together so that now, both intake valves are now following the

"normal" camshaft lobe instead of just one of them. When in VTEC,

since the "normal" cam lobe has the same timing and lift as the

intake cam lobes of the SOHC non-VTEC engines, both engines have identical

performance in the upper powerband assuming everything else is the same.

With the later VTEC-E

implementations, the only difference it has with the earlier VTEC-E is that the

second "normal" cam profile has been replaced with a "wild"

cam profile which is identical to the original VTEC "wild" cam

profile. This in essence supersedes VTEC and the earlier VTEC-E implementations

since the fuel and low RPM torque benefits of the earlier VTEC-E are combined

with the high performance of the original VTEC.

3-Stage VTEC

3-Stage VTEC is a version

that employs three different cam profiles to control intake valve timing and

lift. Due to this version of VTEC being designed around a SOHC valve head,

space was limited and so VTEC can only modify the opening and closing of the

intake valves. The low-end fuel economy improvements of VTEC-E and the

performance of conventional VTEC are combined in this application. From idle to

2500-3000 RPM, depending on load conditions, one intake valve fully opens

while the other opens just slightly, enough to prevent pooling of fuel behind

the valve, also called 12-valve mode. This 12 Valve mode results in swirl of

the intake charge which increases combustion efficiency, resulting in improved

low end torque and better fuel economy. At 3000-5400 RPM, depending on load,

one of the VTEC solenoids engages, which causes the second valve to lock onto

the first valve's camshaft lobe. Also called 4-valve mode, this method

resembles a normal engine operating mode and improves the mid-range power

curve. At 5500-7000 RPM, the second VTEC solenoid engages (both solenoids now

engaged) so that both intake valves are using a middle, third camshaft lobe.

The third lobe is tuned for high-performance and provides peak power at the top

end of the RPM range.

Honda i-VTEC

(intelligent-VTEC)[3] has

VTC continuously variable timing of camshaft phasing on the intake camshaft of

DOHC VTEC engines. The technology first appeared on Honda's K-series four-cylinder

engine family in 2001 (2002 in the U.S.). In the United States, the technology

debuted on the 2002 Honda CR-V.

VTC controls of valve lift

and valve duration are still limited to distinct low- and high-RPM profiles,

but the intake camshaft is now capable of advancing between 25 and 50 degrees,

depending upon engine configuration. Phasing is implemented by a computer-controlled,

oil-driven adjustable cam sprocket. Both engine load and RPM affect VTEC. The

intake phase varies from fully retarded at idle to somewhat advanced at full

throttle and low RPM. The effect is further optimization of torque output,

especially at low and midrange RPM. There are two types of i-VTEC K series

engines which are explained in the next paragraph.

The K-Series engines have

two different types of i-VTEC systems implemented. The first is for the

performance engines like in the RSX Type

S or the Civic Si and the other is for economy

engines found in the CR-V or Accord.

The performance i-VTEC system is basically the same as the DOHC VTEC system of

the B16A's; both intake and exhaust have 3 cam

lobes per cylinder. However the valvetrain has the added benefit of roller

rockers and continuously variable intake cam timing.

Performance i-VTEC is a combination of conventional DOHC VTEC with VTC.

Performance i-VTEC is a combination of conventional DOHC VTEC with VTC.

The economy i-VTEC is more

like the SOHC VTEC-E in that the intake cam has only two lobes, one very small

and one larger, as well as no VTEC on the exhaust cam. The two types of engine

are easily distinguishable by the factory rated power output: the performance

engines make around 200 hp (150 kW) or more in stock form and the

economy engines do not make much more than 160 hp (120 kW) from the

fact.

R-series

The Honda R engine is an inline-four engine launched in 2006 for the Honda Civic (Non-Si). It is fuel injected, has an aluminum-alloycylinder block and cylinder head, is a SOHC 16-valve design (four valves per cylinder) and utilizes Honda's i-VTEC system. The R series engine has a compression

ratio of 10.5:1, features a "drive by wire" throttle system which

is computer controlled to reduce pumping losses and create a smooth torque curve. The engine uses many

technologies to improve economy. Piston rings are given an ion plating, weight

is reduced with plastic and aluminum parts and variable length

intake manifolds that maintain ram air at a

wide rpm range. The automatic transmission model is rated at California Air

Resources Board (CARB) ULEV-2 (Ultra Low

Emissions Vehicle) with fuel economy 25 mpg-US (9.4 L/100 km; 30 mpg-imp)

city, and 36 mpg-US (6.5 L/100 km;

43 mpg-imp) highway. It also uses the same computer (engine control unit) controlled distributorless coil-on-plug ignition as the Honda K-series engines.

The Honda R engine is an inline-four engine launched in 2006 for the Honda Civic (Non-Si). It is fuel injected, has an aluminum-alloycylinder block and cylinder head, is a SOHC 16-valve design (four valves per cylinder) and utilizes Honda's i-VTEC system. The R series engine has a compression

ratio of 10.5:1, features a "drive by wire" throttle system which

is computer controlled to reduce pumping losses and create a smooth torque curve. The engine uses many

technologies to improve economy. Piston rings are given an ion plating, weight

is reduced with plastic and aluminum parts and variable length

intake manifolds that maintain ram air at a

wide rpm range. The automatic transmission model is rated at California Air

Resources Board (CARB) ULEV-2 (Ultra Low

Emissions Vehicle) with fuel economy 25 mpg-US (9.4 L/100 km; 30 mpg-imp)

city, and 36 mpg-US (6.5 L/100 km;

43 mpg-imp) highway. It also uses the same computer (engine control unit) controlled distributorless coil-on-plug ignition as the Honda K-series engines.

The Honda R engine is an inline-four engine launched in 2006 for the Honda Civic (Non-Si). It is fuel injected, has an aluminum-alloycylinder block and cylinder head, is a SOHC 16-valve design (four valves per cylinder) and utilizes Honda's i-VTEC system. The R series engine has a compression

ratio of 10.5:1, features a "drive by wire" throttle system which

is computer controlled to reduce pumping losses and create a smooth torque curve. The engine uses many

technologies to improve economy. Piston rings are given an ion plating, weight

is reduced with plastic and aluminum parts and variable length

intake manifolds that maintain ram air at a

wide rpm range. The automatic transmission model is rated at California Air

Resources Board (CARB) ULEV-2 (Ultra Low

Emissions Vehicle) with fuel economy 25 mpg-US (9.4 L/100 km; 30 mpg-imp)

city, and 36 mpg-US (6.5 L/100 km;

43 mpg-imp) highway. It also uses the same computer (engine control unit) controlled distributorless coil-on-plug ignition as the Honda K-series engines.

The Honda R engine is an inline-four engine launched in 2006 for the Honda Civic (Non-Si). It is fuel injected, has an aluminum-alloycylinder block and cylinder head, is a SOHC 16-valve design (four valves per cylinder) and utilizes Honda's i-VTEC system. The R series engine has a compression

ratio of 10.5:1, features a "drive by wire" throttle system which

is computer controlled to reduce pumping losses and create a smooth torque curve. The engine uses many

technologies to improve economy. Piston rings are given an ion plating, weight

is reduced with plastic and aluminum parts and variable length

intake manifolds that maintain ram air at a

wide rpm range. The automatic transmission model is rated at California Air

Resources Board (CARB) ULEV-2 (Ultra Low

Emissions Vehicle) with fuel economy 25 mpg-US (9.4 L/100 km; 30 mpg-imp)

city, and 36 mpg-US (6.5 L/100 km;

43 mpg-imp) highway. It also uses the same computer (engine control unit) controlled distributorless coil-on-plug ignition as the Honda K-series engines.

i-VTEC with Variable

Cylinder Management (VCM)

In 2003, Honda introduced

an i-VTEC V6 (an update of the J-series)

that includes Honda's cylinder deactivation technology which closes the valves

on one bank of (3) cylinders during light load and low speed (below

80 km/h (50 mph)) operation. According to Honda, "VCM technology

works on the principle that a vehicle only requires a fraction of its power

output at cruising speeds. The system electronically deactivates cylinders to

reduce fuel consumption. The engine is able to run on 3, 4, or all 6 cylinders

based on the power requirement. Essentially getting the best of both worlds. V6

power when accelerating or climbing, as well as the efficiency of a smaller

engine when cruising." The technology was originally introduced to the US

on the 2005 Honda Odyssey minivan, and can now be

found on the Honda Accord Hybrid, the 2006 Honda Pilot, and the 2008 Honda

Accord. Example: EPA estimates for the 2011 (271 hp SOHC 3.5L) V6 Accord

are 24 mpg combined vs. 27 in the two 4-cylinder-equipped models.

In 2003, Honda introduced

an i-VTEC V6 (an update of the J-series)

that includes Honda's cylinder deactivation technology which closes the valves

on one bank of (3) cylinders during light load and low speed (below

80 km/h (50 mph)) operation. According to Honda, "VCM technology

works on the principle that a vehicle only requires a fraction of its power

output at cruising speeds. The system electronically deactivates cylinders to

reduce fuel consumption. The engine is able to run on 3, 4, or all 6 cylinders

based on the power requirement. Essentially getting the best of both worlds. V6

power when accelerating or climbing, as well as the efficiency of a smaller

engine when cruising." The technology was originally introduced to the US

on the 2005 Honda Odyssey minivan, and can now be

found on the Honda Accord Hybrid, the 2006 Honda Pilot, and the 2008 Honda

Accord. Example: EPA estimates for the 2011 (271 hp SOHC 3.5L) V6 Accord

are 24 mpg combined vs. 27 in the two 4-cylinder-equipped models.

i-VTEC i

AVTEC

The AVTEC (Advanced VTEC)

engine was first announced in 2006.[6] It

combines continuously variable valve lift and timing control with continuously

variable phase control. Honda originally planned to produce vehicles with AVTEC

engines within next 3 years.

Although it was speculated

that it would first be used in 2008 Honda Accord, the vehicle instead utilizes

the existing i-VTEC system.

VTEC System Operation

What is valve?

General Defination

A valve is

a device that regulates, directs or controls the flow of a fluid, liquid or

gases in certain close area.

Internal combustion

engine’s valve

A valve

that control the flow of gasses into the internal combustion chamber and out of

internal combustion chamber . Open and close of the valve is control by the

rotation of the cam at the top of the valve.

How VTEC System Operates??

At low engine speeds, the

pin is retracted, disengaging the middle rocker arm. The valves are operated by

the two outside, low-profile cams for a low valve lift. Low profile cam is used

at low engine speed to reduce the fuel consumption and more efficient.

When the engine speed

increases the pressure of hydraulic oil increases and pushes the pin.The pin

make the middle rocker arm to operates and high cam profile is on for a high

valve lift.

Valve lift is now operates

in an extended time because the high cam profile is used make the mixture of

fuel and air in the combustion chamber increases and give more extra power.

From this picture we can

see at low engine speed the valve lift is open at small range compare to the

valve lift at high engine speed that open at big range and more time duration

of cam lift.

VTEC OPERATION STEP DIAGRAM

Components Identification.

- Function Of each parts

- Valve

Control

the flow of gasses in and out of internal combustion chamber . Open and close

of the valve is control by the rotation of the cam at the top of the valve.

- Valve Stem

A valve

stem is a self-contained valve which opens to

admit gas to a chamberand is then automatically closed and kept sealed by the pressure in

the chamber, or a spring,

or both, to prevent the gas from escaping.

- Valve Retainer

They are

a split tapered retainer, that keeps the valve spring attached to the valve.

Without them the valve would fall into the cylinder damaging the piston &

ruining the cylinder wall.

- Valve Spring

A helical

spring used to hold closed a valve in the cylinder head of an

internal-combustion engine. Also prevent from valve float at high engine RPM

speed.

- Return Spring

Used to

push the pin of middle rocker arm at normal position when engine speed at low

speed or below the pressure of hydraulic oil.

- Slide Pin

Used to

engaged and disengaged the middle rocker arm at certain engine speed that

control by hydraulic pressure to engaged and disengaged.

- Slide Pin Holder

Used to

hold the slide pin when the middle rocker arm is used.

- Stopper Pin

Used

to stop the pin at the correct position.

- Inner Shim

A valve

shim is a disc of hardened metal of precisely calibrated height used

to adjust the clearance between the back side of the cam-lobe and the valve on

which it operates where the cam-lobe operates directly on the valve without an

intermediate rocker arm. The shim sits atop a shim bucket which itself sits

atop the valve-stem and moves up and down within a machined bore.

- Valve Lifter

Transfer the vertical load to the cylinder head in order to prevent buckling of

the valve.

- Spool valve

A valve that controls the direction of hydraulic

fluid flow. A spool valve consists of cylindrical spools that

alternately block and open channels in the hydraulic system.

- Cam Shaft

Transforming rotary motion into linear motion or vice-versa. In the internal combustion chamber cam used to open and close the valve based on the timing that is set on the rotation of the cam.Cam shaft

- Rocker Arm ( Primary and secondary)

A pivoted

lever used in an internal combustion engine to transfer cam or pushrod motion

to a valve stem. In Honda VTEC engine, Primary and secondary rocker arm used on

low degree cam profile at low engine speed.

- Rocker Arm (Middle)

A pivoted

lever used in an internal combustion engine to transfer cam or pushrod motion

to a valve stem. In Honda VTEC engine, Middle rocker arm used on high

degree cam profile at high engine speed.

Above is the picture of the

latest Honda model in Malaysia. Honda Accord 2014

Everything you need to know

about the specifications and full capacities of our cars.

There in some latest

technology that they invent to improve the Honda Product:

- Earth Dreams Technology

Earth

Dreams Technology is a suite of advanced technologies that enhances both the

driving performance and fuel economy, thus offering the driver more torque with

better fuel efficiency.The all

the engine give more benefit in fuel efficiency but does not sacrifice the

engine performance

- Shift Hold Control

Reduces

unnecessary gear shift-up in cornering and supplies acceleration immediately

after making a turn. The paddle shift system allows you to change gears

manually without removing your hands from the steering wheel. This

technology help the driver to give more concentration while taking corner

- Drive-By-Wire (DBW)

DBW

technology allows for smoother shifting via an electronic throttle control. The

linkage to the intelligent Grade Logic Control enhances the drive and reduces

gear hunting.This technology help

ecu to calculate the ratio mixture inside the combustion chamber based on

throttle respond indirectly make the engine more efficient.

- Eco Assist

The ECO Assist Guide

changes lights depending on how conscientious the drive is. The longer it stays

on green, the more efficient the drive becomes.This give guide to

drive more manner and help to reduce the fuel consumption.

Designed to dramatically

reduce low frequency noise in the cabin and control the engine order sound in a

linear way, so you can enjoy a serene drive every time.

G-CON absorbs and spreads

collision energy, helping minimize injury for everyone − occupants, passengers

in other cars, bikers and pedestrians.

This invention as mention

before help to minimize the injury to the driver passenger and the accident’s

victim. This invention is really good to save life.

A small camera is mounted

on the passenger mirror, enhancing the side view while reducing blind spots,

making it easier and safer when you change lanes.

The Accord's 8-inch screen

features a 180 ° multi-angle view for safer reversing.

Honda Civic Type-R 2015

- Honda has revealed a trio of new turbocharged VTEC engines, including the one that will be used in the 2015 Civic Type R.While the US is getting revamped Civic sedans and coupes, European customers will soon be able to opt for the 2015 Type R with its new Earth Dreams 2.0-liter turbo engine producing more than 276 horsepower. Honda has also made sure to give the car a styling that matches its powerful engine with a more aggressive front end, massive fender flares and a liftgate wing with unusual airplane-like canards.The Civic Type R will be the first model in Europe to have one of Honda's all-new VTEC TURBO engines from Honda's Earth Dreams Technology range. This 2 litre, direct injection, 4-cylinder turbo engine is expected to have class-leading output in excess of 280ps and will be EURO 6 compliant.Speaking during recent testing at the Nurburgring, Germany, Honda's WTCC driver Gabriele Tarquini, gave his first driving impressions 'The car and the characteristics of the car were fantastic. I was really impressed by the power and the torque of the engine but also by the set-up they achieved...The car is very pointed on the front and very fast to change direction'. 'This car is very close to my racing car and you can feel very well the DNA of Type R.'

This Honda Civic Type-R has different various color.

Turbo Engine of Honda Civic Type-R

- It's fair to say that in recent years, Honda has been viewed as a laggard when it comes to engine and gearbox development, seemingly missing the boat on direct-injection, forced-induction and high gear-count transmissions, among other things. But under its Earth Dreams banner, the Japanese automaker is showing new vigor, with the latest proof being this trio of just-announced powerplants. 19-Nov-2013 Today Honda announced the introduction of three all-new VTEC TURBO engines as part of its growing Earth Dreams Technology range. These new engines come in three capacities; 1 litre, 1.5 litre and 2 litre, and will deliver a dynamic performance, as well as class-leading output and fuel economy. All three engines will be direct-injection petrol turbos, utilising variable valve motion technology such as Honda's refined VTEC technology. Together with Honda's 1.6 litre diesel engine and hybrid technology, these new turbo engines will be applied on a number of future global models, depending on local market requirements and vehicle characteristics.Based on a completely new engine structure and utilising its newly developed turbo systems, Honda has downsized its engines and produced a highly efficient 1 litre direct-injection, 3-cyclinder turbo engine as well as a 1.5 litre direct injection, 4-cyclinder turbo engine. Both engines have low friction throughout and are able to achieve class-leading output and environmental performance.The first VTEC TURBO set to come to Europe will be the high-output 2 litre, direct injection, 4-cyclinder turbo engine, which will appear in the forthcoming Civic Type R. A highly efficient and highly responsive engine, it will have an output in excess of 280ps and will be EURO 6 compliant.

Honda Civic Type-R Turbo Engine 2.0 litre

Honda Civic Type-R Turbo Engine 1.5 litre

Honda Civic Type-R Turbo Engine 1.0 litre

Conclusion

In

conclude, As we know Honda is the master of the valve technology. Ikuo Kajitani the

mastermind said that,"four-valve engines are known as high-revving,

high-output machines. And for that reason we knew it would be quite difficult

to achieve low-end performance if the engine's displacement were too small”. Based

on this question, Vtec system is born step by step, Research by Research and

now Honda VTEC engine have made a lot of improvement for Normal aspirated

engine that give a competition on Turbo and supercharge engine around the

world. By this system, VTec system give more respond on High rpm Engine but

does not sacrifice the low and mid engine speed. Combination of two type of cam

degree profile, the mixture inside the combustion chamber can be increases

based on need and give extra power . High profile degree camshaft is such as force

Induction that give extra power to the engine at high end speed..

This technology is Honda forte and this technology is done by other manufacture

with same concept but with different part and operation .Honda VTEC

system is the true and original system Made BY Honda.

By this technology, Normal

aspirate engine also can have a good engine respond and more efficient smooth

engine and fuel efficient engine that VTEC system give to Honda user

References

- http://engineringcorner.blogspot.com/2011/09/v-behaviorurldefaultvmlo.html

- http://www.honda.com.my/

- http://en.wikipedia.org/wiki/VTEC

- http://world.honda.com/automobile-technology/VTEC/

- http://en.wikipedia.org/wiki/Valve

- http://en.wikipedia.org/wiki/3-stage_VTEC

- http://www.b18c5eg.com/VTEC/3stagevtec.html

- http://asia.vtec.net/article/ivtec/

- http://www.honda.com/newsandviews/article.aspx?id=7349-en

- http://www.autoblog.com/2013/11/19/honda-new-turbo-vtec-engines-civic-type-r/