LINCOLN VALVE TECHNOLOGY

- Basically Lincoln car are apply Variable Valve Timing (VVT) fot their valve technology.

Variable Valve Timing - The Next Phase

- Variable Valve Timing For

Performance Applications

Once upon a time, picking a cam for a given engine combo was all

about compromise: improve top-end power at the expense of low-end torque, run

well at wide-open throttle but sacrifice idle stability and part-throttle

cruise driveability, trade off performance for gas mileage, run hard or run

clean. Thanks to OEM-developed variable valve timing (VVT), it doesn't have to

be that way anymore.

VVT is a generic term for various

concepts that allow changing the advance, overlap, and even (in the case of

some import overhead-cam engines) the duration and lift of a four-stroke

internal-combustion engine's intake and exhaust valves while the engine is

operating. This technology has been under development for more than a century

(a variation was tried out on some early steam engines), but it is only within

the last 20 years or so with the advent of sophisticated electronic sensors and

engine management systems that it has become practical and effective.

Why VVT?

The initial impetus

to put VVT systems into production cars was the ever-increasing pressure to

meet environmental goals and fuel efficiency standards while still maintaining

reasonable performance. With today's VVT systems, engines are so efficient at

reducing emissions that the notorious separate EGR valve has become virtually

extinct; VVT provides sufficient passive EGR charge dilution that considerable

fuel economy, idle, and emissions benefits are achieved without the need to

resort to clumsy add-on devices. Although not originally its main intent, as

applied to performance, VVT allows running a relatively radical cam that still

maintains a stable idle and low-speed driveability. VVT can be coupled with

another new technology, active fuel management, which allows selective

deactivation of multiple cylinders under cruise when full power isn't required.

Combined, these technologies should permit the survival of large-displacement

V-8 engines for the foreseeable future.

Changing The Cam Cycle

The most common VVT

implementation is advancing and retarding the intake and exhaust valves'

opening and closing points. Advancing the cam means moving the lobe centerlines

to produce earlier valve timing events during the engine's cycle; retarding a

cam is the opposite. On engines with the intake and exhaust cam lobes ground on

the same billet, a VVT mechanism advances or retards the entire cam (intake and

exhaust) equally. Although the lobe centerlines change in relation to top dead

center, the lobe-separation angle (LSA, the distance between the intake and

exhaust lobe centerlines) remains the same. LSA changes are only possible if

the intake and exhaust lobes are ground independently (not on a common billet).

Until recently, this required a DOHC (dual overhead cam) setup.

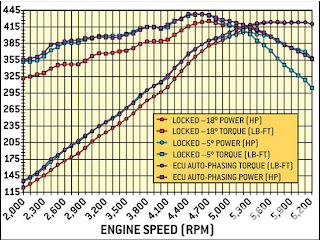

Generally, you'd want to advance

a cam for more bottom end, higher vacuum, and better idle characteristics.

Retarding a cam aids the top end. A typical production cam optimized for an

advance/retard VVT system is usually ground with reduced overlap, with VVT

retard dialed in as needed to maintain or enhance the top-end power.

For those systems capable of also

changing the lobe separation, a smaller lobe-separation angle increases

overlap. Given the same duration, separation and overlap are inversely

proportional. More overlap decreases low-rpm vacuum and response and improves

the signal provided by the fast-moving exhaust to the incoming intake charge in

the midrange, often providing noticeable engine acceleration improvements. Less

overlap can increase efficiency by reducing raw fuel seepage into the exhaust

and improve low-end response due to less reversion of the exhaust gases into

the intake port. In terms of emissions, you obviously don't want raw fuel

getting into the exhaust, but under certain conditions, introducing overlap at

low rpm to dilute the intake charge induces passive EGR and improves mileage,

albeit at the expense of low-end torque. It's a fine balancing act.

Hydraulically actuated cam phasing is the preferred method for variably

advancing or retarding a cam. An electronically controlled hydraulic valve

(sometimes referred to as an oil control valve or OCV) directs engine oil into

a camshaft phaser assembly that replaces the timing chain's upper sprocket.

Inside the phaser cavity is a rotor that rotates within a stator as needed to

advance or retard the cam. An additional advance/retard calibration table or

map that relates cam lobe and crank position to engine speed is added to the

computer (ECU or electronic control unit).

Things To Watch Out For

One potential VVT problem is that

the ECU assumes the use of a mild cam, permitting a fairly large latitude of

advance and retard. This can cause piston/valve interference issues when

installing an aftermarket cam with more duration, overlap, and lift.

Workarounds include reflashing the factory computer to tighten up the allowable

range of cam movement, adding a mechanical phase-limiting device, and/or

installing custom pistons with deeper valve notches.

Valve spring configuration is

also critical on VVT engines. Hydraulically actuated phasers are susceptible to

over-aggressive valvespring seat pressures, which may overwhelm the oil

pressure-generated hydraulic forces needed to correctly actuate the phaser

mechanism. With the factory computer, this generates a fault code and puts the

cam into full retard. Special valvesprings are therefore required that can

support a hotter cam without overwhelming the VVT system. Bearing this in mind,

let's take a closer look at VVT technology as it's applied on typical domestic

engines used by hot rodders.

the GM phaser assembly (A) is retained by a central bolt (B) containing the control spool valve, a filter and a check valve. In this design the valve is separate from the electronic force motor (C), a solenoid that's installed in the redesigned front cover. The solenoid has an armature that pushes on the spool valve based on input from its control unit that is connected to the ECU. This includes a camshaft position sensor (D), which interfaces with a four-tooth cam sensor wheel (E) to recognize the position of the camshaft relative to the crankshaft.

-variable valve timing